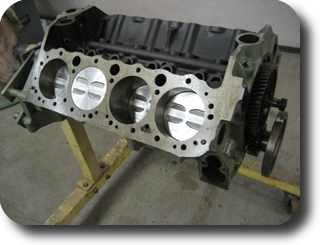

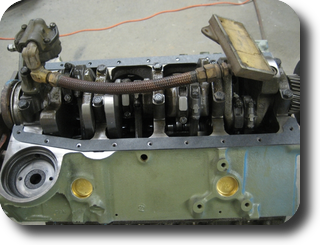

Back from the machine shop.

(06-MAR-2009)

|

Prepping the block for paint. (07-MAR-2009)

|

|

|

Block primed with DuPont 2580CR urethane primer.

(06-MAR-2009)

|

|

|

|

|

Pressure washing the engine block.(14-MAR-2009)

|

|

Intake manifold has a large hole in the bottom of the plenum. It will

have to be replaced.

|

|

|

(28-MAR-2009)

|

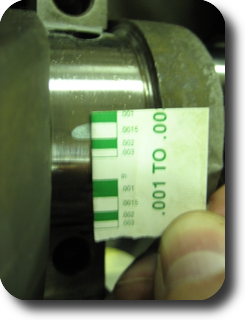

Cut and place a strip of plastigauge on a main bearing cap.

|

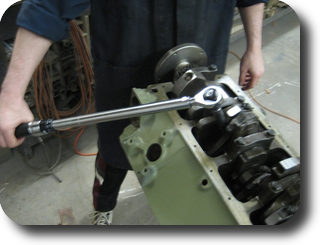

Torque the main bearing cap bolts to 65 ft/lbs.

|

Determinine the clearance by matching up the compressed plastigauge strip with the

plastigauge kit's ruler. Crankshaft main bearing clearance : 001" - .004"

|

Coat the camshaft running surfaces with assembly lube and install it in the engine.

|

Install rear oil seal.

|

Locate the camshaft gear's timing mark and mark it with some Liquid Paper.

|

Install the crankshaft and main bearing caps. Ensure that the crankshaft and

camshaft timing marks are aligned properly.

|

Measure piston ring gap. Reccommended clearances are usually included with the

piston ring set.

|

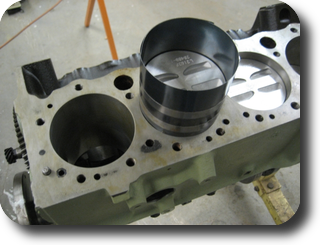

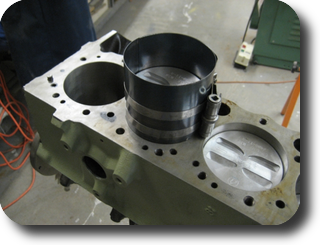

Install piston without rings to check bearing clearances. Stock cast pistons were upgraded to

forged units (.030" oversize).

|

Cut and place a strip of plastigauge on the connecting rod cap bearing.

|

Torque the cap bolts and measure the connecting rod side clearance (two rods) : .008" - .014"

|

Connecting rod bearing clearance : .001"-.004"

|

Installing the piston with a piston ring compressor. (03-APR-2009)

|

|

|

Installing the connecting rods.

|

|

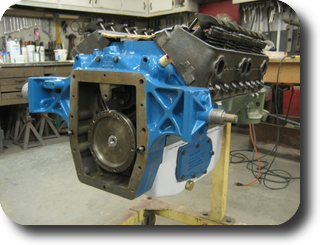

Short block completed.

|

|

|

|

| Engine Clearances |

Cyl | Main

bearing | Top

Ring |

Middle

Ring | Connecting

Rod | Rod Side

Clearance |

| 1 | .0015 | .017 | .017 | .001 | .009 |

| 2 | .002 | .017 | .016 | .001 |

| 3 | .0015 | .018 | .018 | .001 | .010 |

| 4 | .002 | .016 | .016 | .0015 |

| 5 | .003 | .017 | .018 | .001 | .010 |

| 6 | | .017 | .017 | .001 |

| 7 | | .018 | .016 | .0015 | .011 |

| 8 | | .017 | .017 | .0015 |

| Crankshaft end play | .003" |

|

| |

Exhaust manifolds and other painted parts were chemically stripped and sandblasted.

(09-APR-2009)

|

Parts were primed with DuPont 2580CR DTM urethane primer.

(10-APR-2009)

|

Aluminum oil pan was etched with DuPont Metal Conditioner prior to priming. This

promotes paint adhesion on bare aluminum parts.

|

Flywheel.

|

To stabilize the color and kick up the topcoat, we sprayed a white basecoat. Paint

is DuPont Imron urethane.

|

We couldn't get an Imron color match to the Chris-Craft blue, so we used a

Nason acrylic enamel which was custom mixed using DuPont's Kodak color match system.

|

Rebuilt heads. New valves, valve guides and valve seats.

(11-APR-2009)

|

Marine head gasket.

|

Cylinder heads torqued to 65 ft/lbs.

|

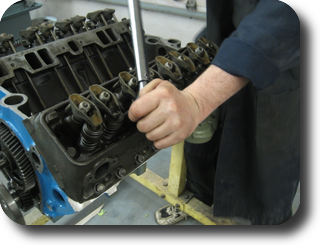

We completed the valve train by replacing the old solid lifters with a Comp Cams solid

lifter kit. The original pushrods and rocker arms were in good shape so they were

cleaned and reused.

|

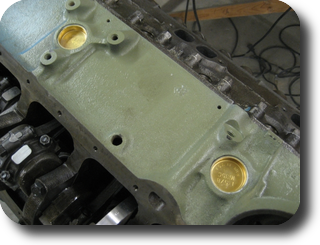

Frost plug holes were scuffed to bare metal.

(13-APR-2009)

|

|

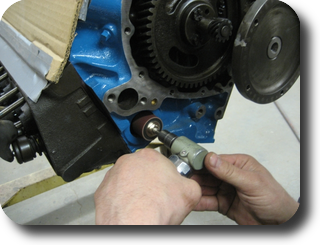

Brass frost plugs installed with a socket used as a drift.

|

|

Oil pump, pickup hose and pickup screen assembly installed.

|

Oil pan installed. We prepainted the block's front face because it will be

partially obstructed when the rear cover is installed.

|

Rear cover installed.

|

As soon as the engine is buttoned up, the cylinder heads will be primed, remaining

non-blue parts will be painted white and then topcoated with blue paint.

|

Water pump bead blasted. (17-APR-2009)

|

Bare sandblasted/bead blasted parts.

|

Parts primed with DuPont 2580CR DTM urethane primer.

|

Base coat of white Imron urethane.

|

|

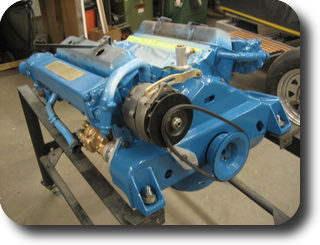

Nason acrylic enamel custom mixed to match Chris-Craft Blue.

|

|

|

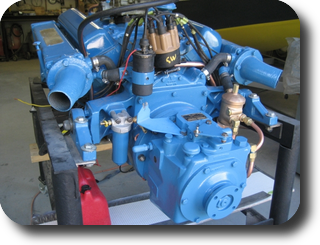

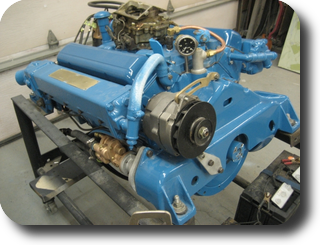

Engine block painted.

|

Assembly begins. (22-APR-2009)

|

|

|

|

Water pump sprayed with Nason Urethane Clear to protect the raw aluminium and bronze parts.

|

Polyester body filler applied to the valve covers.

|

Primed, base-coated white Imron and topcoated with blue acrylic enamel.

|

|

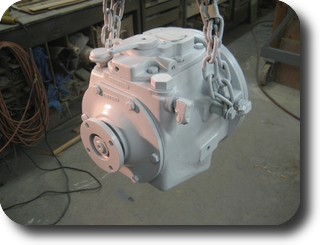

Paragon HF7 transmission bead-blasted and chemically stripped.

|

Primed.

|

Base-coated.

|

Top coated.

|

|

Mounted on the engine run stand and re-assembled.

|

|

|

|

|

|