*** WARNING *** This page is Under Construction ! Content will be added as it becomes available.

| Home | Bottom |

Sections

|

Before costing out performance engine parts for your 283, check out the pricing for 350 crate engine performance long blocks. You'll need better flowing cylinder heads and a more aggressive camshaft to increase power levels.

Here are a few issues you'll have to resolve if you're not using the stock engine :

|

Q : I have a Chris Craft 283 flywheel forward engine, 185 HP with a old Paragon transmission.( 1:1, inline, RH) in a Riva Ariston. I want to replace it for a Velvet 71C. Can you tell me where to get a adapter flange to fit/mount the Velvet on the CC engine. Are there more things to change or does it fit with a correct adapter flange ?

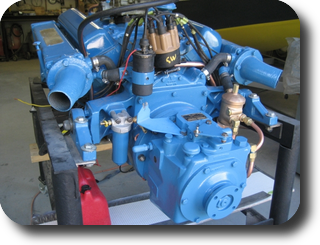

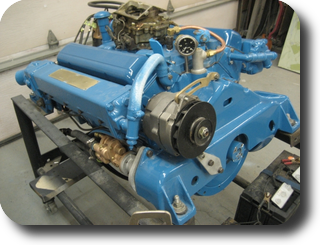

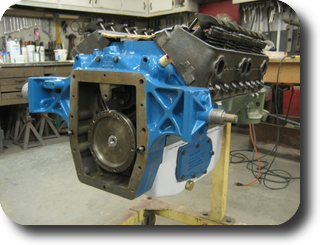

A : Photos of a rear cover which mates to a Velvet Drive transmission. We picked up two flywheel forward V8's several years ago. Both had Paragon reduction gear units. The Paragon drive drive plate (mounted to the crankshaft nose) has the same spline count as the Velvet Drive input shaft. No other mods are required.

The number stamped on the cover is 3572 A.

The Paragon transmissions are obsolete, parts are getting harder to find to fix them and the input power ratings are quite low. They are also expensive to have rebuilt as very few shops still work on them. We had a Paragon HF7 rebuilt several years ago and it set us back $1500 CAD. We could have bought a reconditionned Velvet Drive for half of that, but the owner wanted to keep it original. The Paragon also has a peculiar reverse band adjustment that must be adjusted when the boat is put back into service. The transmission can be severely damaged if it isn't adjusted properly. Much easier to find parts for the Velvet Drives and the input power rating is much higher.

As for transmission lengths, you will find the specifications listed on our Transmission Page (first table, Specs column) :

Transmission Page

We have two plates but we'll be using them on our engines. You may want to call Robert Henkel to see if he has any parts. We could have a plate machined at a machine shop, but the cost (and shipping) would be high.

Robert Henkel (Harsens Island, Michigan USA) is our main contact for Chris Craft parts. We've ordered a new aluminum low-rise intake manifold and a complete flywheel forward gasket set as well as hard to find molded rubber hoses (used) for a 283HO restoration. Give him a call and let him know what you're looking for. I'm sure he can source just about any used part you can think of.

Peter Henkel Inc, 810.748.3600, ask for Robert,

chris-craft-parts.com

References

| 4.3 V6 | 283 CID V8 | |

|---|---|---|

| Engine & trans overall length | 33-1/4" | 40-1/4" |

| Bellhousing to front engine mount | 22-1/2" | 28" |

| Bellhousing to to front face | 17-12" | 22-1/4" |

| Crankshaft centerline - Front | 12" | 12" |

| Trans output flange centerline | 3-1/2" | 3-1/2" |

| 71C transmission length | 15-1/4" | |

We've had several requests from Glen-L builders wishing to extend the hull length and pondering where to locate the engine,

or adding a transmission to a design that was never intended to have one (direct drive) such as the 15' LOA

Glen-L Cracker Box.

We needed to find some answers, so frame offsets from the Glen-L plans were loaded into an ASCII file and imported into HullForm95

hull modelling software. The hull was balanced and the hull CB (Center of Buoyancy) was noted after the hull hydrostatics report was

run. The HullForm input file was converted and imported into DelftShip. The CB was confirmed

by running the hull hydrostatics report.

The hull weight, hull CB, engine, transmission, passenger and fuel tank weights and locations were loaded into our Excel Hull CG Locator spreadsheet to derive the hull CG. The spreadsheet calculates the hull CG for a single driver and hull CG for a driver & co-pilot. The hull CG-to-CB distance is included in the drawings below :

Click image to enlarge.

Notes :Modelling the stock length (15') Cracker Box Hull reveals that the hull CB is located at 58" from the transom. The boat is usually fitted with a direct-drive flywheel-forward V8 (no transmission is used) with the propeller shaft coupled directly to the front of the crankshaft snout via a chain coupler. The 600 pound engine CG is located at 70" from the transom. Hull CG is located at 68 1/8" from the transom and 9 3/4" forward of the CB.

Substituting a flywheel forward V8 equipped with a Velvet Drive 71C inline transmission will increase the engine/transmission weight to 700 pounds. The engine/transmission CG is located at 70" from the transom. Hull CG is located at 68 1/4" from the transom and 9 7/8" forward of the CB.The shaft angle in the drawing can be verified by using our Shaft Angle Table.

- Take the length dimension from the aft end of the strut to the shaft entry point e.g. 30",

- Scroll down to 6.75" in the Drop column,

- Locate a value that is close to 30" in the Length column,

- The shaft angle for that length is listed in the Angle column. Angle is between 12.5° and 13°.

The following shaft layout diagrams are for the same hull stretched 10%.

Click image to enlarge.

Click image to enlarge.

The flywheel forward installation is the preferred installation as the engine CG is very close to the hull CB. The shaft angle is lower which will ensure that the boat won't have any handling quirks associated with steep shaft angles. For the same shaft angle, the flywheel aft engine is installed 8 inches further ahead than the flywheel forward engine. In this installation, this places the engine CG 8 inches ahead of the hull CB. As a general rule, the engine CG should be located on or aft of the hull CB.

Here's partial ouput from the spreadsheet we developed to calculate the boat's CG :

Here's a link the spreadsheet :

Moment Study for the Glen-L Cracker Box (PDF)

Feel free to contact us if

you are modifying the plans and wish to determine the optimum engine location without adversely affecting hull balance.

Follow the link below for Flywheel-Forward Rebuilding Notes :

| Home | Top |

The 6.18" dia. damper for 26 spline transmissions as used on flywheel forward Flagship, Chris Craft & Perkins

engines are hard to find.

The 6.18" dia. damper for 26 spline transmissions as used on flywheel forward Flagship, Chris Craft & Perkins

engines are hard to find.